Check New BoMs Against Your Existing Material Master

Partium checks your new Bill of Materials (BoMs), cross-referencing each part against your current material master

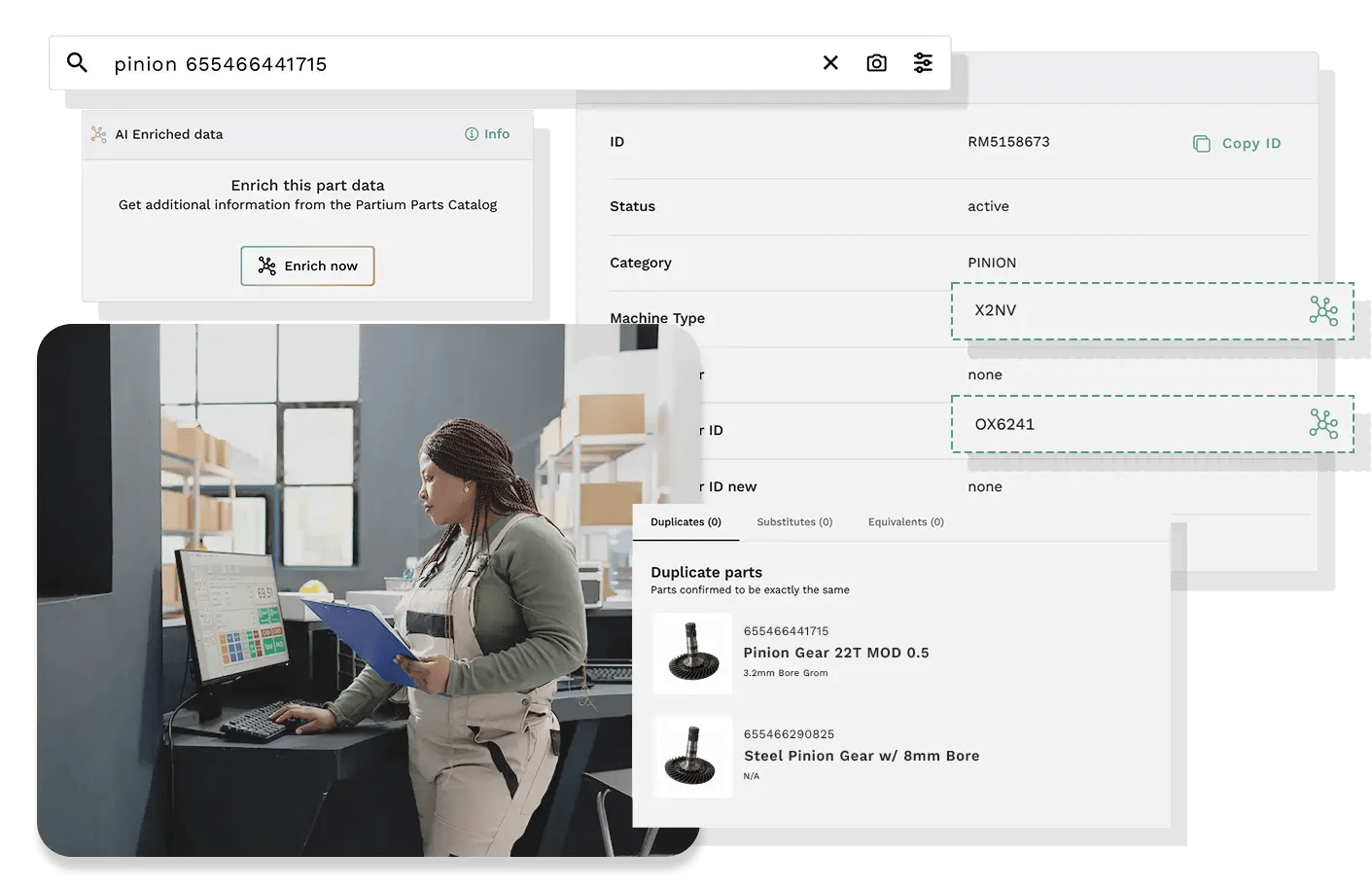

Check New BoMs Against Your Existing Material Master

Partium checks your new Bill of Materials (BoMs), cross-referencing each part against your current material master.

Review Duplicate Results at a Glance

Instantly view parts flagged as duplicates. Skip redundant entries and focus only on what's new

Review Duplicate Results at a Glance

Instantly view parts flagged as duplicates. Skip redundant entries and focus only on what's new.

Skip the Duplicates and Only Import Genuine New Parts

Easily update your material master by importing only verified new parts, avoiding unnecessary duplication and maintaining data integrity

Skip the Duplicates and Only Import Genuine New Parts

Easily update your material master by importing only verified new parts, avoiding unnecessary duplication and maintaining data integrity

Partium Insights reveals what your data isn’t telling you—from missing Original Part Manufacturer (OPM) info to inconsistent entries and catalog gaps. With clearer visibility into your material master, you can identify what needs fixing, uncover standardization opportunities, and reduce costs by discovering alternative sources for the same parts.

Quick Time to Value - And a Massive Impact

17% Potential Duplicates

Partium proposes potential duplicate data and allows for a quick identification of duplicate materials so you can cut down on spend, consolidate suppliers, share parts and more

37% Lower Procurement Costs

Partium supports you in your quest to identify the original parts manufacturer so you can drive down procurement/sourcing costs

|

|

Upload your data |

|

|

Run an AI-powered assessment |

|

|

Review insights on duplicates, gaps, & inconsistencies |

|

|

Operate with confidence—merge, enrich, and optimize |

Total hours per year spent searching:

Hours saved with Partium intelligence:

FAQs

-

What is data cleansing in spare parts management?

Data cleansing refers to the process of identifying and correcting errors, duplicates, and inconsistencies in your materials master data. It includes standardizing naming conventions, enriching missing attributes, aligning formats, and removing obsolete or redundant entries, resulting in a clean, consistent, and searchable parts catalog.

-

Why is data cleansing important for MRO and supply chain teams?

Poor-quality data leads to duplicate purchases, increased downtime, sourcing mistakes, and inflated inventory. Clean data enables faster part identification, better procurement decisions, improved search performance, and smoother operations across MRO, supply chain, and asset management systems.

-

What are the most common data issues companies face?

- Duplicate part entries under different names

- Missing or incomplete part attributes

- Inconsistent naming conventions or units of measure

- Obsolete or non-stocked items cluttering the catalog

- Difficulty linking similar or alternative parts across systems

-

How can data cleansing reduce costs?

Clean data helps identify duplicate or unnecessary parts, consolidate suppliers, and improve demand forecasting. This directly lowers inventory carrying costs, reduces emergency purchases, and improves sourcing efficiency.

-

How often should we clean our materials data?

Ideally, data cleansing should be part of an ongoing process, not a one-time fix. Our 'always on' AI will continually clean your data as it is updated.

-

Can data cleansing help us identify alternative parts or substitutes?

Yes! Clean, enriched data helps surface similar or alternative parts across your catalog, especially when enriched with OEM specifications or standardized naming. This can support maintenance flexibility, reduce dependency on single suppliers, and improve part availability.

-

What’s the difference between data cleansing and data enrichment?

Data cleansing is focused on correcting, removing, or standardizing existing data.

Data enrichment enhances that data by adding missing information—such as manufacturer details, specs, categories, or cross-references.

Both are critical for a complete and accurate parts database. -

Can AI help automate data cleansing?

Absolutely. AI can quickly detect potential duplicates, suggest attribute corrections, and enrich missing data using reference catalogs or learned patterns, saving time and reducing the burden of manual data cleanup.