Partium Parts Intelligence Use Cases

The Numbers Say It All

70% faster part search. 50–80% fewer duplicates. Up to 35% in cost savings.

Partium helps real teams solve real parts problems — across maintenance, aftersales, procurement, and beyond.

Explore the use cases driving these results.

Select a Use Case to Explore:

| Challenge | Partium Impact | |

|---|---|---|

Maintenance & MRO |

lost maintenance time, frequent misorders, dirty data, duplicates, disconnected systems |

Up to 70% faster part identification, 40% fewer service errors, and 50–80% fewer duplicates across your master data |

Aftersales |

Slow response times, high support load, customer frustration |

Cut resolution time by 60% and reduce ticket volume by 30–50% |

DIY / Web Self-Service |

Low conversion, Abandoned carts, unclear product matching |

Boost conversions by 25–40% with AI-powered visual part search |

Logistics |

Misidentified parts, manual lookup, and tribal knowledge slow down picking, packing, and returns |

Reduce lookup time from minutes to seconds with AI-powered identification, cutting picking errors, accelerating order fulfillment, and streamlining reverse logistics |

OEM Conversion |

Locked into expensive suppliers, limited alternatives, rising part costs |

Achieve up to 35% cost savings by identifying cross-compatible alternatives |

Data Cleansing |

Manual processes, inconsistent records, high effort, no scalability |

Cleanse millions of records in days, not months — and keep them clean |

Visual Recognition of Train components

How ÖBB Train Tech uses artificial intelligence for clarification about spare parts.

Read Case Study

Warehouse Optimization & Increased Efficiency

How Wien Energie managed to streamline their procurement processes using Partium.

Read Case Study

Leveraging AI in Train Maintenance

In a challenging environment with time-critical maintenance, even experienced technicians can struggle.

Read Case Study

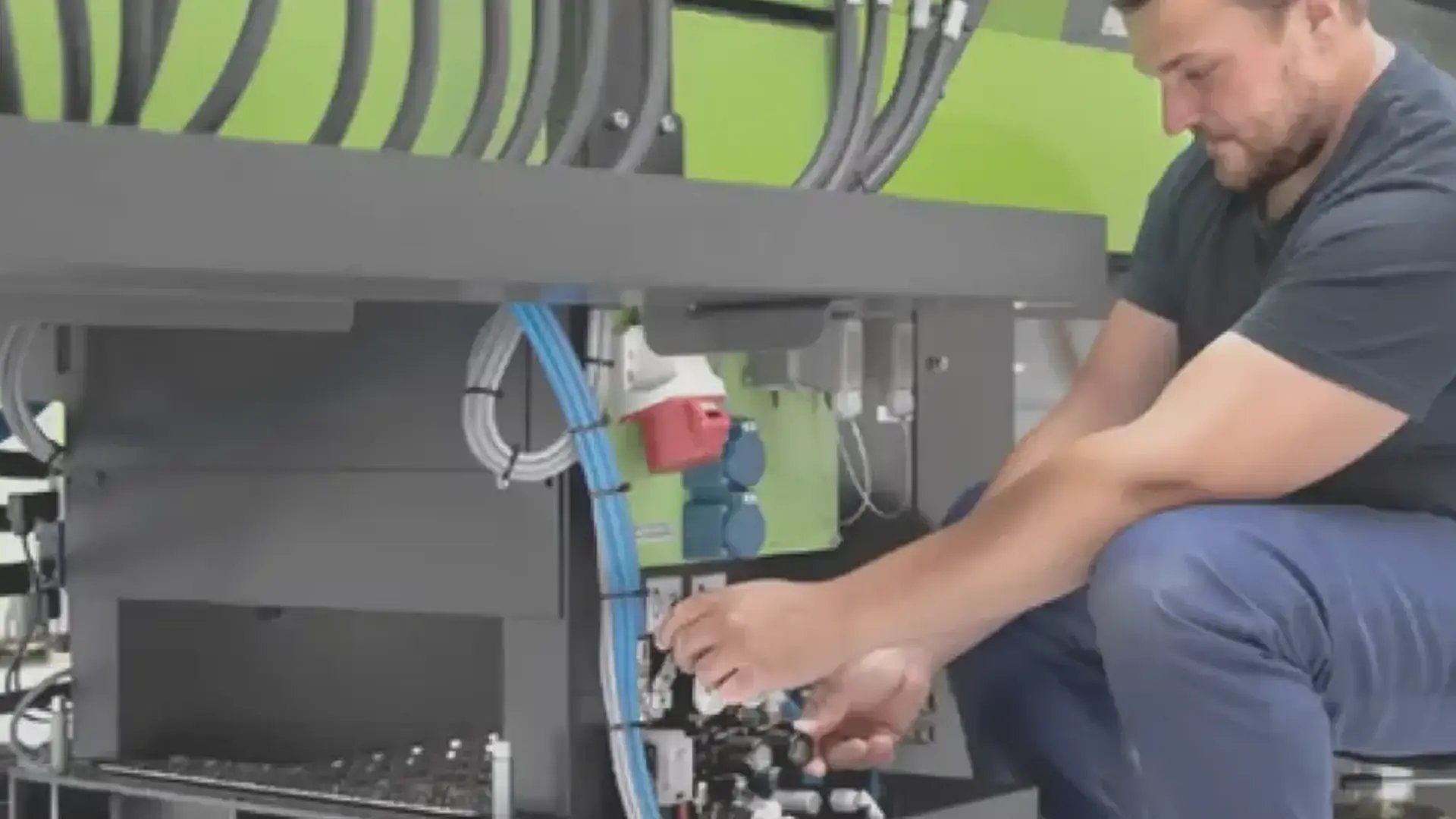

How ENGEL uses Partium to drive Part Sales

ENGEL was looking for a way to grow their aftersales parts business sustainably.

Read Case Study

How GF Machining Solutions optimized part Identification

GF Machining Solutions is one of the world's leading providers in the mold-making industry.

Read Case Study

How Home Depot managed to optimize part search

Partium’s advanced part recognition technology is fully integrated into Home Depot’s customer app.

Read Case StudyTotal hours per year spent searching:

Hours saved with Partium intelligence: