Case Study:

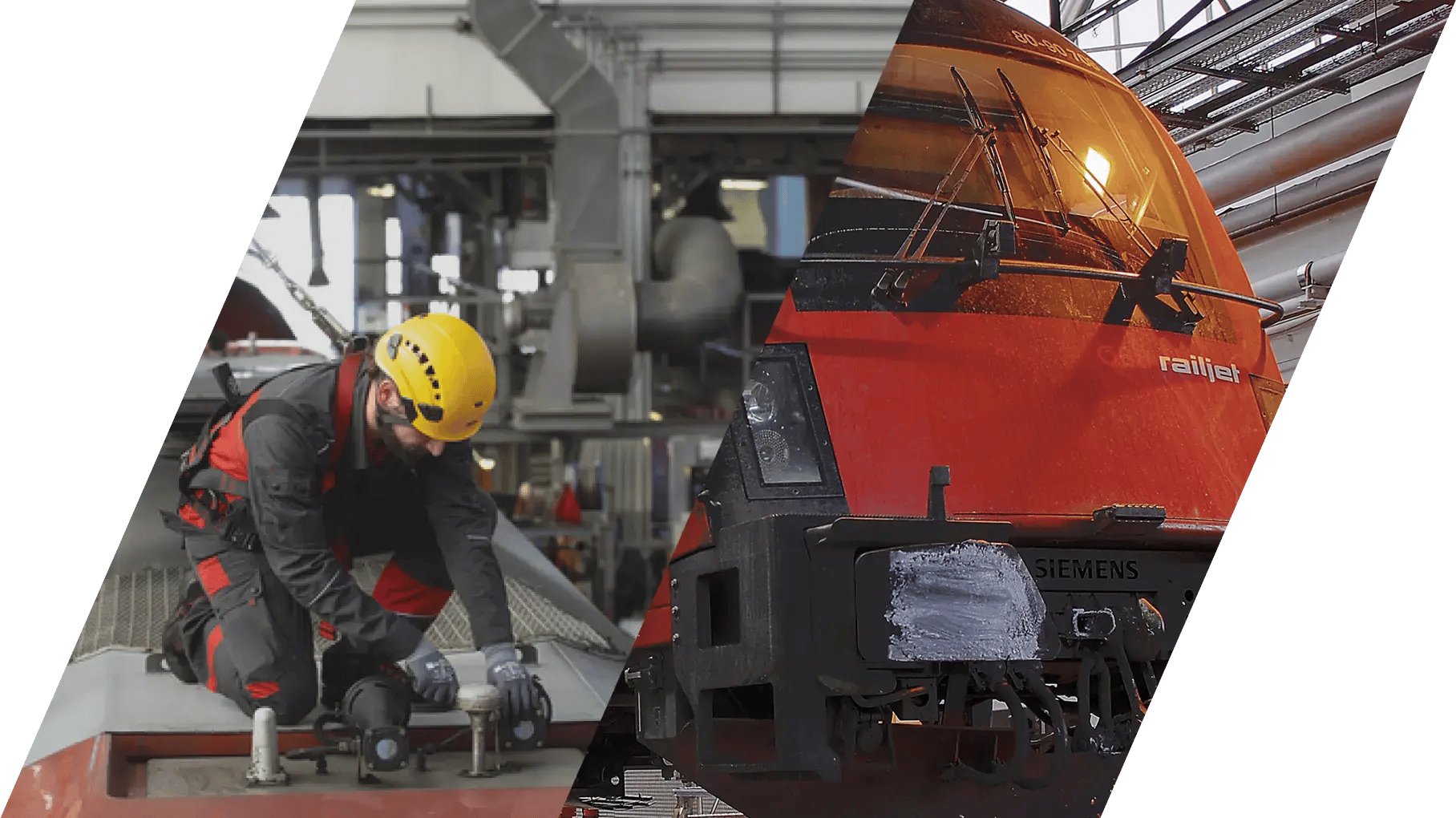

ÖBB X Partium

Visual Recognition of Train Components

How ÖBB Train Tech uses artificial intelligence for clarification about spare parts

At a Glance

ÖBB-Technische Services-GmbH is the ÖBB Group's center of technical expertise, responsible for the maintenance and development of rail vehicles. Decades of experience, state-of-the-art technologies, and a tightly integrated service network form the foundation for professional, cost-effective, and safe maintenance.

ÖBB Train Tech maintains an extensive inventory of spare parts to enable economical maintenance services well beyond Austria’s borders. Rail companies from across twenty European countries already rely on this support.

Table of Contents

The Challenge

Strategic Challenge:

Demand in the maintenance market is rising, while competition and cost pressures continue to intensify amid rapid technological advancement. At the same time, shifting mobility behaviors are playing a key role in achieving climate goals—making rail transport increasingly important for the future.

With the right strategy, ÖBB Train Tech aims to stay ahead of these trends and reinforce its ambition to further strengthen its position as a leading service partner for customers across the European market.

Operational Challenge:

As trains become increasingly complex, the demands on maintenance technicians correspondingly rise. Highly specialized experts take care of specific areas and rail vehicles at every location.

Vehicle technicians in the workshops process repair orders, identify materials, and are supported by experienced team leaders.

The Solution

To increase efficiency and expand its service capabilities, ÖBB Train Tech is investing heavily in future-oriented technologies such as digitization and automation.

As part of this initiative, ÖBB Train Tech sought a solution that would enable all employees to accurately identify and locate spare parts — including the correct part numbers. Based on a recommendation from Deutsche Bahn, they discovered Partium: a mobile solution that supports multiple search methods, including image search, text input, OCR, QR codes, barcodes, and more. The system is designed to be effective for both experienced technicians and junior staff alike.

Partium has already been rolled out to team leaders and selected employees at three locations. These early adopters are now responsible for training vehicle technicians involved in maintenance operations.

Benefits for Users

1. Self-Service Tool

With Partium, technicians can find spare parts faster, more easily, and more independently—without having to involve colleagues.

2. Journeys Saved

The mobile solution allows vehicle technicians to search for parts and additional information onboard the train, saving unnecessary travel between trains, workshop computers, and warehouses.

3. Fewer Inquiries in Day-to-Day Work

The expertise of team leaders in recognizing materials is becoming less necessary. Due to demographic changes, a significant amount of knowledge will also leave the company in the coming years.

4. Easier Onboarding Through Image Search

Vehicle technicians who have only learned German as a second or third language can identify products independently using photos. Even inexperienced vehicle technicians who do not have a full grasp of rail-specific terminology are able to find the right parts without the support of experts, thanks to Partium”s image search. Partium makes the first years after training the vehicle technicians in maintenance easier.

5. Expert Knowledge is Conserved

Knowledge from long-term employees is gradually stored in Partium.

6. Accelerated, More Efficient Processes

ÖBB Train Tech benefits from significantly reduced search times in maintenance and increased operating times for vehicles.

From Image to Identification: Visual Recognition of Train Components

When vehicle technicians were searching for train parts, it often resulted in lengthy and tedious searches. They had to navigate through various databases, lists, and their own applications. Additionally, the process extended to spare parts warehouses and involved not only supervisors but also several colleagues from other departments, such as the warehouse. This process tied up a lot of capacities in the company, not to mention the long distances to cover between trains, workshops, offices, and spare parts warehouses.

ÖBB-Technische Services-GmbH quickly realized that Partium's spare parts search would solve these problems and expedite the search for parts, as well as enhance cooperation between internal teams.

Partium allows users of all experience levels and different language skills to search by image or text and apply filters, enabling them to find parts in a matter of seconds or minutes. Having information about the part number, storage location, and part availability on the train is crucial. Instead of resorting to phone calls, emails, or messages to describe the part, or, in some cases, even removing and bringing it to the warehouse for visual comparison, maintenance teams can now easily locate parts using Partium. Once successfully identified, the spare part can be requested from the warehouse.

Outlook

Partium is gradually being rolled out to more locations and users within ÖBB. The plan involves even better integration into the ERP system (SAP), particularly focusing on the master data.

Additionally, it will be integrated into the SAM order management system, including the implementation of a reservation function.