Case Study:

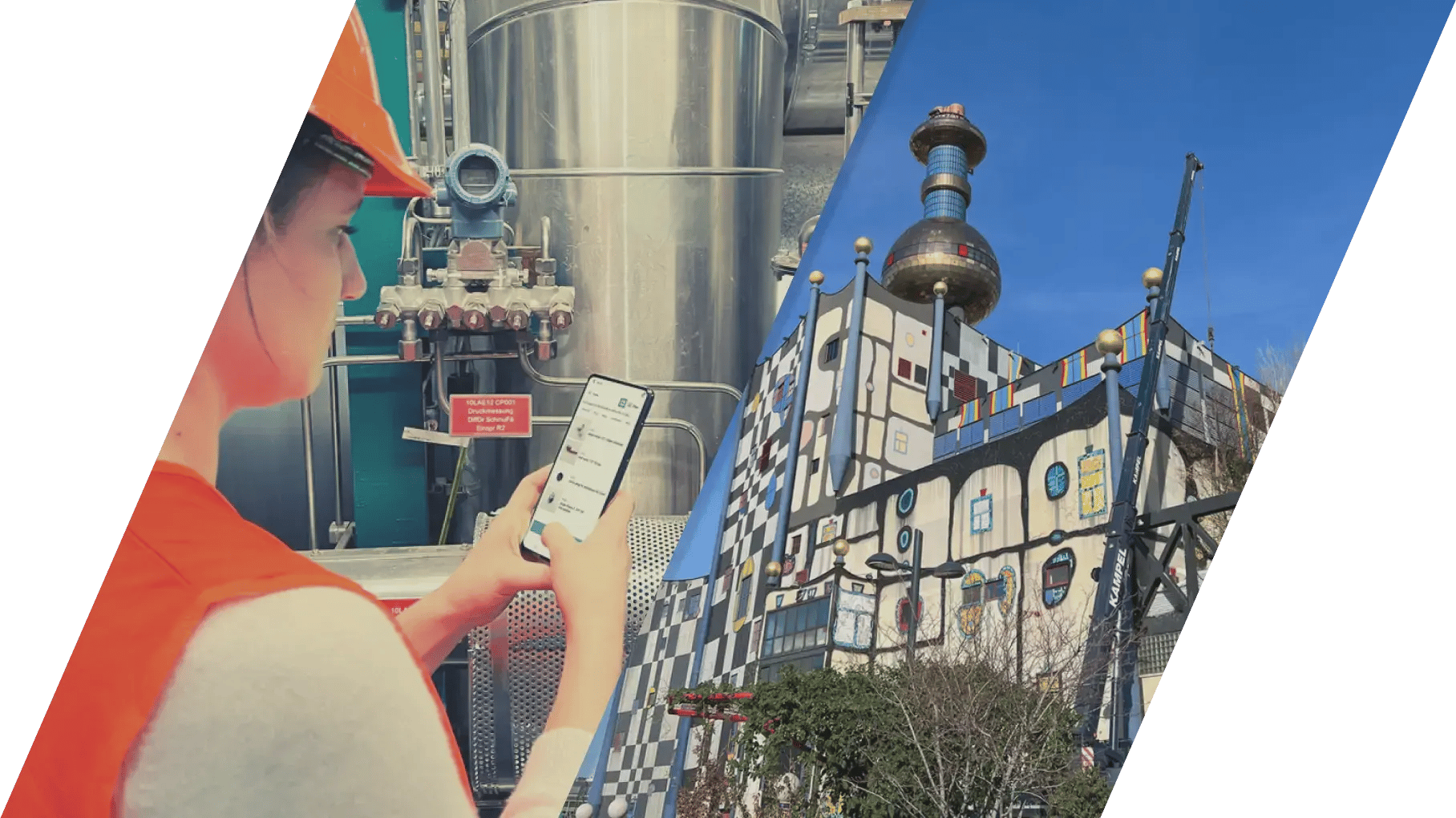

Wien Energie X Partium

Warehouse Optimization & Increased Efficiency

How Wien Energie managed to streamline their procurement processes using Partium.

At a Glance

Wien Energie is Austria’s largest energy provider. Two million people, 230,000 trade and industrial customers, and 4,500 agricultural businesses rely on them.

Table of Contents

The Challenge

The consolidation of 1,400 m² floorspace to only 300 m² made the maintenance technicians’ job incredibly hard.

Before searching for a part, maintenance technicians could walk to the warehouse and look at all the spare parts available. With the warehouse consolidation, they were forced to know in advance what part they were looking for so they could order it from the supply chain team.

This wasn’t easy at all. Maintenance technicians and the supply chain teams went above and beyond, trying to identify parts using WhatsApp, email, and phone. In some cases, parts were dismounted and sent to the warehouse staff via bus, or technicians went to the warehouse by car. This process was labor- and cost-intensive, as well as time-consuming and inefficient.

The Solution

Wien Energie was looking for an improved solution to search for parts without physically seeing them in the warehouse. That’s when they came across Partium.

Partium is a mobile solution that offers different search modalities, such as image and semantic search. It works for experienced as well as less-experienced staff.

In April 2022, Wien Energie introduced Partium. In a short time, 220 employees working in "Maintenance & Logistics" and 280 employees working in "Renewable Energies" benefited from a significantly reduced time searching for parts. They can find and locate parts in 15-30 seconds or less.

Benefits for Wien Energie

1. A Fast & Efficient Way to Search for Parts

With Partium, technicians can find spare parts faster, more easily, and more independently. There is no need to drive to the warehouse anymore to look for a part.

2. Mobile & User-Friendly Solution

The mobile solution allows users to search for parts anywhere, no matter where they are. Partium is easy to use and, thanks to its different search modalities, suitable for experienced and less-experienced maintenance staff.

3. Better Communication Within the Teams

Maintenance teams can search for and request parts conveniently via the app instead of using WhatsApp, emails, and phone calls to communicate.

4. Cost-Efficient

Thanks to Partium, Wien Energie successfully consolidated its warehouses. They not only reduced costs by minimizing space requirements but also gained the advantage of more streamlined processes.

5. Streamlined & Efficient Procurement Processes

Procurement processes are now accelerated, streamlined, and documented.

6. Knowledge Management

Specific knowledge about replacement parts is often connected to a few experts within the company. Partium helps prevent the effects of brain drain and retirement by providing a tool everyone can use to find parts.

From Tedious Spare Part Searches to Finding Parts in Under a Minute

At Wien Energie, finding a spare part once required time-consuming manual searches across multiple inventory locations, databases, and often involved consulting colleagues or supervisors.

As they began a warehouse consolidation project aimed at saving costs by reducing over 1,000 m² of floor space, they sought a mobile solution accessible to everyone. Their goal was to locate parts faster and gain real-time, mobile visibility into warehouse inventory locations.

Creating Added Value Directly at the Base

Partium is a tangible, easy-to-implement digital solution that delivers immediate value at the operational level. Implementation took just around four weeks.

Thanks to Partium, Wien Energie benefits not only from reduced inventory and warehouse costs but also from streamlined procurement processes and increased maintenance productivity.