3 min read

Lifecycle in Workflow: Turning NRND, PCNs & LTBs into Predictable Operations

Linda Piercy

:

Nov 19, 2025 6:34:06 AM

Quick Summary

- NRND (Not Recommended for New Designs), PCNs (Product Change Notices), and LTBs (Last‑Time Buys) are everyday realities—not edge cases

-

The only durable answer is lifecycle in workflow: show status, alternates (with FFF notes), and lead times inside ERP/EAM and field apps, not in side spreadsheets.

-

Replace one‑off cleanups with continuous governance: lifecycle checks at approval, dedupe + drift alerts, and a monthly obsolescence review aligned to IEC 62402 / DMSMS practices.

-

Start small: triage your top 200 parts, pre‑approve alternates, and add a mobile “Use Alternate” and “Raise LTB” action. Outcomes follow.

Table of Contents

The Lifecycle Reality in Heavy Industry

Plants, fleets, and grids outlive the components inside them. Electronics churn faster than asset lifetimes; suppliers consolidate; materials change. Waiting for end‑of‑life to announce itself at the loading dock is how you get line‑downs, rush buys, and redesigns you didn’t plan for.

Acronyms that Actually Matter (NRND, PCN, LTB, FFF)

-

NRND—Not Recommended for New Designs: Still purchasable, but on a path to EOL. Fine for installed base; risky for new work.

-

PCN—Product Change Notice: Manufacturer tells you a change is coming (materials/process/spec). Early signal = options.

-

LTB—Last‑Time Buy: Final order window. Miss it and you’re in spot‑buy land.

-

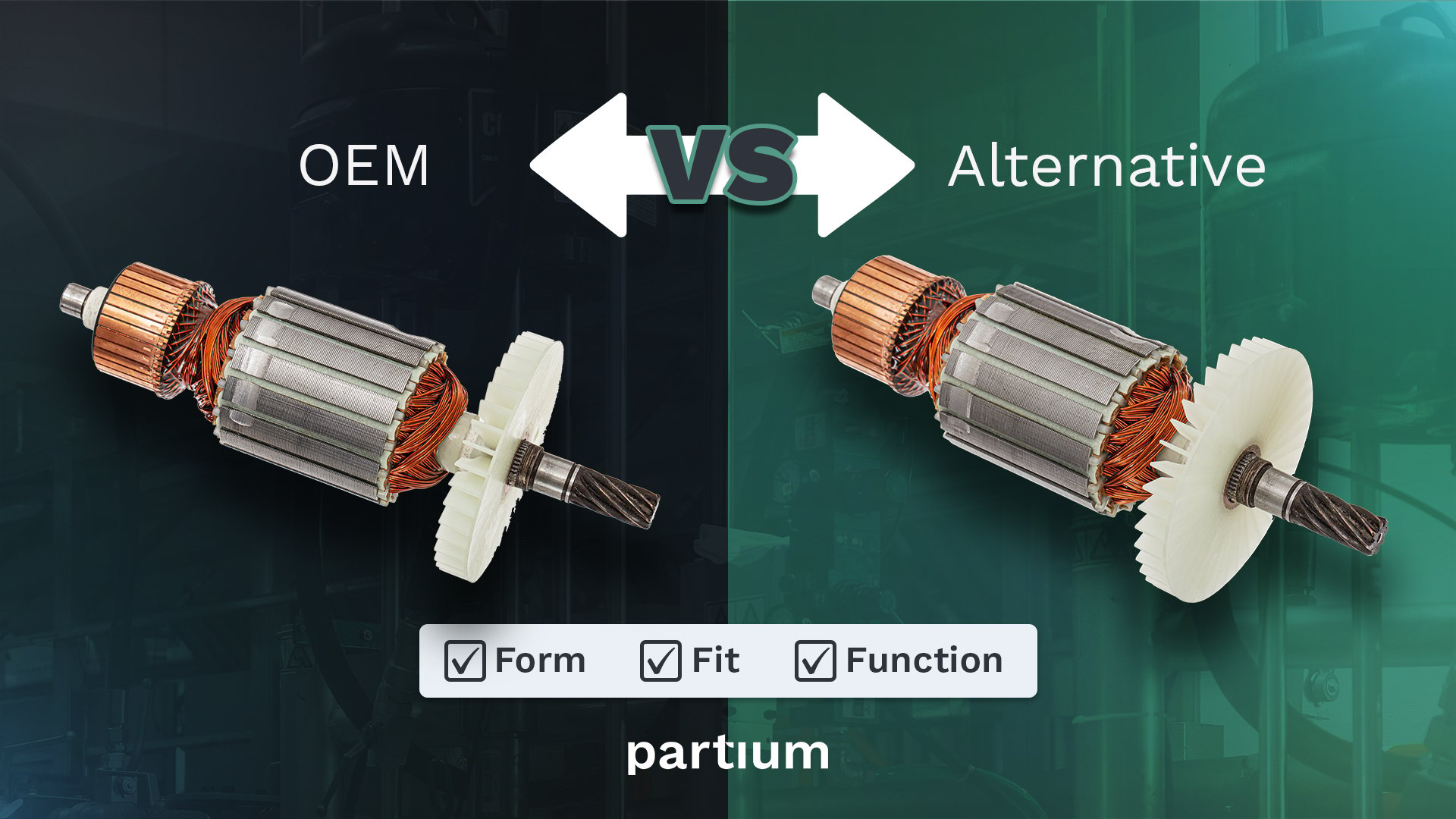

FFF—Form, Fit, Function: The discipline behind approved alternates. If FFF is clear, alternates become decisions, not debates.

Why Cleanups Fail (and Governance Wins)

One‑off “cleans” give you a nicer snapshot; they don’t change the movie. New parts and catalogs land; reality drifts. Governance means lifecycle checks at the point of approval, dedupe on the slice you actually use, drift alerts, and monthly obsolescence reviews (top‑10% SKUs). Boring beats heroic.

Lifecycle in Workflow: What Good Looks Like

Where the work happens:

-

Tech tablet: Lifecycle badge (Active/NRND/EOL), two verified alternates with short FFF notes, lead time, Use Alternate button, photo+note capture.

-

Requisition / approval screen: Status + last PCN summary, LTB countdown, side‑by‑side OEM vs alternate (price, lead time, lifecycle), tariff/classification hint.

-

Data & governance view: Dedupe on active SKUs, drift alerts, monthly review queue, audit trail of mitigations.

The Program: Detect → Assess → Mitigate → Monitor

-

Detect: Watch for NRND/EOL, PCNs, LTBs; maintain a watchlist for critical SKUs.

-

Assess: Impact on uptime/cost; simple risk score (design life, # of mfrs, lead times).

-

Mitigate: Approve alternates (FFF), plan LTB quantities, multi‑source, or trigger redesign.

-

Monitor: Make lifecycle a KPI; review top‑10% SKUs monthly; close the loop in ERP/EAM.

Actionable Steps You Can Take Now

-

Triage 200 parts (highest usage + criticality). Flag NRND/EOL.

-

Approve 1–2 alternates for the top 20 parts; add short FFF notes.

-

Mobile first: add Use Alternate and photo+note to the tech app.

-

Approval guardrail: block or flag POs without a lifecycle/alternate check.

-

One monthly review: top‑10% SKUs; assign owners and deadlines.

-

Dedupe on the live slice: start with the 10k SKUs you actually touch.

KPIs that Predict a Calmer 2026

-

% POs lifecycle‑checked before approval (make this default).

-

% critical parts with verified alternates on file.

-

Duplicate rate in the top active SKUs.

-

Mean time tech → fix and mis‑order rate.

-

Line‑down events avoided (track one‑liners in work orders).

No‑BS Callouts (Hard Truths)

-

NRND is the warning, not the cliff. Treat it that way.

-

Alternates without FFF are rumors. Document or don’t use them.

-

If lifecycle isn’t visible in ERP/EAM, it doesn’t exist.

-

One‑off cleans are theater. Governance is policy + habit.

Final Thoughts

Lifecycle isn’t a project; it’s a discipline. Put the truth where decisions are made—on the tablet and in the approval flow—and you’ll trade drama for routine. That’s how plants stay up, fleets keep moving, and budgets stop bleeding on surprises.

Further Reading

Obsolescence management standard — IEC 62402

-

What it is: The international standard for through-life obsolescence management (detect → assess → mitigate → monitor).

-

Why it matters: It’s the backbone for turning ad-hoc cleanups into a continuous program.

-

Link: IEC 62402:2019 overview and abstract (IEC Webstore). IEC Webstore

(Preview listing also available via ANSI.) ANSI Webstore

DMSMS practice (DoD approach to obsolescence)

-

What it is: The U.S. Defense guidebook for Diminishing Manufacturing Sources & Material Shortages (DMSMS)—processes, roles, and metrics.

-

Why it matters: A mature, battle-tested playbook you can adapt to civilian industry.

-

Link: SD-22 DMSMS Guidebook (Mar 2024), Defense Acquisition University. DAU

-

Portal: DMSMS Knowledge Sharing Portal (DKSP) — tools, templates, and data elements. DAU+1

Field enablement — FFF guidance & lifecycle data fields

-

What it is: “Form, Fit, Function (FFF)” definitions + practical parts-management references to structure alternates and approvals.

-

Why it matters: FFF turns alternates from guesses into auditable decisions, and helps you define the data you need (PCN ID/date/link, LTB deadline, approved alternates with FFF notes/approver).

-

FFF definition (contracting/engineering): FAR 27.401 (Form, fit, and function data). Acquisition.gov

-

Parts management standard context: MIL-STD-3018 (historical) and update on its replacement by MIL-STD-11991B (DAU note). Defense Logistics Agency+1

-

Data & tools: DKSP resource index for DMSMS/parts-management templates. DAU

Explore the Solution

Want to see this in action?

👉 Watch the demo or Visit The Parts Intelligence Platform to learn how this solution supports your team with faster, smarter spare part decisions.

Right Part, Lower Cost: How AI-Driven OEM Conversion Cuts Spend Without Adding Risk

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

FFF—Form, Fit, Function: The Discipline Behind Approved Alternatives

Quick Summary FFF (Form, Fit, Function) is the engineering discipline that turns a substitute part from a guess into an auditable decision. “Form” =...