Right Part, Lower Cost: How AI-Driven OEM Conversion Cuts Spend Without Adding Risk

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

3 min read

Linda Piercy

:

Dec 15, 2025 8:56:19 AM

Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval.

Clean the records you actually use (dedupe + enrichment) instead of “boiling the ocean.”

Put lifecycle flags (NRND/PCN/LTB) and FFF notes where buyers decide—inside the requisition/approval flow.

Outcome: up to 35% cost savings, fewer rush buys, and less OEM dependence without risking uptime.

| Challenge | Struggle | Impact with Partium |

|---|---|---|

| Locked into expensive OEMs | Rising costs, few approved alternatives, weak leverage | Identify cross-compatible parts instantly, unlocking up to 35% savings without risking downtime |

| No visibility into viable alternatives | Buyers chase numbers across PDFs and portals | AI-matched alternatives surface in seconds—even without perfect part numbers |

| Duplicates & naming inconsistencies | Same part, different names/prices → bloated inventory | Deduplication + enrichment consolidate records and expose hidden overlap & savings |

| Inflexible supplier relationships | Can’t challenge price hikes or negotiate | Verified cross-references (FFF) restore leverage and reduce single-vendor dependence |

| Time-consuming manual sourcing | Slow quotes and delayed POs | Visual + text + spec search embedded in ERP speeds requests and approvals |

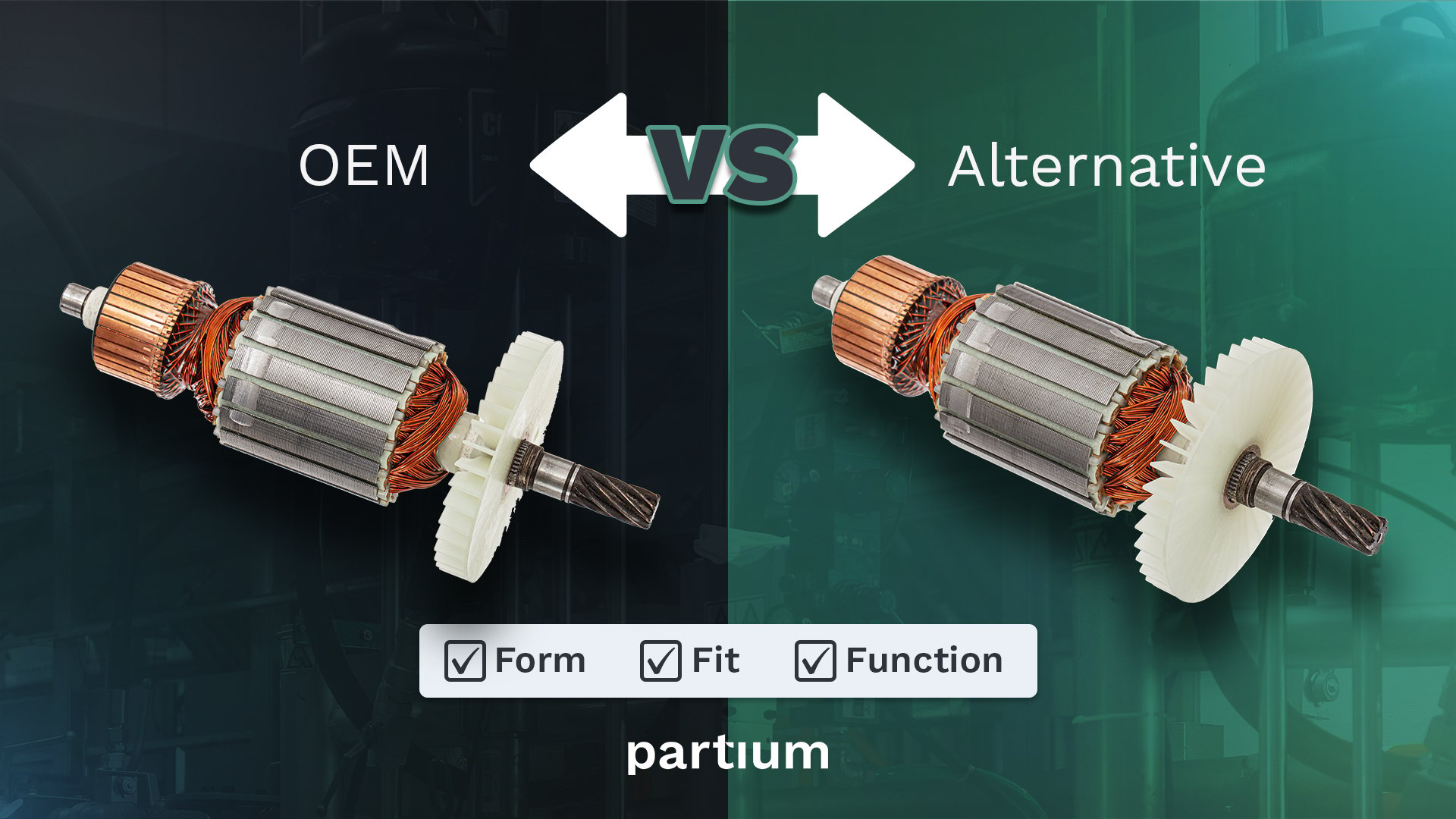

Direct price relief: Showing the OEM and the approved alternative side-by-side changes the conversation from “pay list” to “pick best value.”

Faster cycle time: Photo, partial code, or a couple of attributes → a clean shortlist with verified alternatives.

Controlled risk: FFF notes + lifecycle (NRND/PCN/LTB) are visible inside approvals, making decisions defensible and auditable.

Find equivalents fast: Start from image, OCR fragment, or spec; AI returns the OEM plus cross-compatible alternatives.

Make the data usable: Deduplicate vendor look-alikes; enrich missing specs to compare apples to apples.

Put proof where buyers decide: In the approval screen, show OEM price/lead time vs approved alternative with FFF note and lifecycle badge.

Close the loop: Operate upstream of SAP/Oracle/Maximo; write back clean fields—no big-bang change.

Side-by-side choice: OEM X vs. Alternative Y (same Form/Fit/Function) with price, lead time, lifecycle.

Guardrail: Warn/block if an NRND/EOL requisition lacks an approved alternative or an LTB plan.

Deduped live slice: Focus on the top 10–20k active SKUs that drive 80% of spend.

Evidence trail: Each decision carries its FFF note and data lineage (who, when, why).

Weeks 1–2: Prove it on a narrow slice

Pick a pressured category (e.g., electrical spares).

Align the active records only; run dedupe + enrichment.

Attach approved alternatives to the top 200 items.

Weeks 3–6: Put it in approvals

Show OEM vs. alternative in the requisition.

Add one guardrail: NRND/EOL requires an alternative or LTB coverage.

Weeks 7–12: Expand & measure

Roll to the next category/site.

Track: % POs with an alternative considered, price variance vs OEM, rush buys avoided, lead-time delta.

Savings on converted items: target 10–35% vs OEM list.

POs with an approved alternative visible: target >60% in 90 days.

Duplicate reduction (active slice): ≥20%.

Rush buys avoided: count in work orders.

Lead-time improvement: days saved vs OEM.

Compliance: FFF notes and lifecycle context make approvals more auditable.

Performance: Alternatives are FFF-verified on the canonical record; approver and rationale are logged.

Disruption: Clean the data you actually use first; expand after wins.

A multi-site manufacturer paying list on an OEM valve family had three vendor records for the same equivalent. After dedupe/enrichment and adding FFF-verified alternatives:

Buyers chose the approved alternative with a 12-day faster lead time and 28% lower price.

Rush orders fell 19% in the pilot area.

Standard cost was reset, saving six figures annually.

Final Thoughts

OEM conversion isn’t a moonshot; it’s a workflow change. Put proof where buyers decide—approved alternatives (FFF), price/lead time, and lifecycle flags—and the spend curve bends without risking uptime.

Remember the basics:

Evidence beats opinion: alternatives + FFF note visible at approval.

Clean the live slice first: dedupe/enrich the 10–20k parts you actually use.

Governance, not projects: drift alerts and lifecycle checks keep data clean while you work.

Measure like operators: savings % on converted items, POs with alternatives visible, duplicate reduction, rush buys avoided, lead-time delta.

Start small, prove fast, expand. Pick one painful category, wire the approval view, and track the wins. When the right choice is obvious on screen, buyers choose value—and costs fall.

Next step:

See OEM vs. approved alternative side-by-side in your approval flow. Book a short walkthrough or jump to the OEM Conversion use case to dive deeper.

Further reading:

Use Case: OEM Conversion → https://www.partium.io/use-cases/oem-conversion

Blog hub (find a distinct angle, avoid duplication): https://www.partium.io/blog

Want to compare OEM vs. approved alternative without leaving the workflow? Book a short walkthrough.

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

Quick Summary FFF (Form, Fit, Function) is the engineering discipline that turns a substitute part from a guess into an auditable decision. “Form” =...

Quick Summary NRND (Not Recommended for New Designs), PCNs (Product Change Notices), and LTBs (Last‑Time Buys) are everyday realities—not edge cases