Right Part, Lower Cost: How AI-Driven OEM Conversion Cuts Spend Without Adding Risk

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

3 min read

Linda Piercy

:

Jun 11, 2025 11:47:33 AM

Tariff shocks, supplier instability, and rising raw material costs are creating chaos across global supply chains. In this post, we explore how AI-driven tools and enriched parts intelligence are helping manufacturers, MRO teams, and supply chain professionals adapt faster, reduce risk, and maintain continuity in the face of shifting trade policies.

U.S. tariffs are increasing costs and disrupting critical material flows

AI enables real-time risk analysis and alternative sourcing strategies

Parts intelligence supports faster pivoting with enriched supplier data

Companies using predictive insights can outpace disruption and reduce downtime

Proactive data strategies are now essential to supply chain resilience

Recent U.S. tariffs have dramatically reshaped global supply chains, forcing businesses to rapidly reassess their sourcing, pricing, and production strategies. Across industries, the ripple effects are immediate—and costly.

Automotive: Raw material costs have surged more than 20%, directly affecting profit margins and forcing automakers to adjust pricing models in real time.

Electronics: Tariffs on key components have delayed production schedules and pushed companies to seek diversified suppliers, often at higher costs.

MRO (Maintenance, Repair, and Operations): Extended lead times caused by sourcing disruptions are impacting preventive maintenance schedules and reducing uptime across manufacturing floors.

The consequences go beyond delays—they expose vulnerabilities in global sourcing models that many companies have relied on for decades.

Traditional supply chains aren’t built to handle this level of volatility. Manual tracking, siloed systems, and static sourcing strategies leave companies flat-footed when tariffs strike.

AI-powered platforms offer dynamic visibility into parts availability, real-time pricing shifts, and regional risk indicators. For example, an industrial machinery manufacturer used AI insights to shift its steel sourcing from tariff-affected markets, avoiding a major spike in procurement costs.

Machine learning models can forecast potential impacts of new tariff regulations and simulate supply chain shifts before they happen. One aerospace leader identified supplier vulnerabilities months in advance, securing secondary vendors before tariffs disrupted their primary supply.

By enhancing internal part records with data on alternate sources, compatible specs, and OEM-equivalent items, companies can respond quickly to disruption. Parts intelligence tools turn raw material chaos into structured, actionable decision-making.

Navigating today’s tariff landscape requires precision, speed, and data-driven agility. Here’s how leading teams are doing it:

Identify cost-effective alternatives: Use visual search and AI-driven parts intelligence to find compatible parts or secondary sources instantly.

Enrich sourcing data: Integrate supplier metadata, BOM relationships, and regional availability to ensure sourcing flexibility.

Model trade impacts: Apply predictive analytics to simulate tariff effects and mitigate risk before it impacts procurement cycles.

These aren’t optional strategies—they’re survival mechanisms in a disrupted environment.

AI doesn’t replace supply chain professionals—it makes them more effective. By offloading repetitive tasks like part matching and risk scanning, teams can focus on higher-value work: supplier negotiations, risk scenario planning, and strategic inventory control.

It’s a shift from reactive management to proactive resilience.

Tariff volatility is here to stay. Whether driven by geopolitical shifts, climate regulation, or regional conflict, global sourcing will continue to face headwinds.

Companies that invest now in AI and parts intelligence tools will not only navigate disruptions more smoothly—they’ll turn uncertainty into competitive strength. Visibility, speed, and adaptability are the new cornerstones of supply chain excellence.

Looking to strengthen your strategy for navigating tariffs, global disruptions, and procurement volatility? These additional reads provide real-world insight into how manufacturers and procurement leaders are building smarter, more resilient operations—powered by data, technology, and intelligent sourcing.

The Hidden Costs of Poor Spare Parts Master Data: Six Key Challenges

Tariffs are just one part of the challenge. Inaccurate, inconsistent, or incomplete parts data can quietly erode sourcing efficiency, inflate costs, and limit your agility. This article explores the six critical ways poor master data creates hidden friction across procurement and supply chain workflows.

Harvard Business Review: Rebuilding Supply Chains for Resilience

This essential HBR piece outlines how global leaders are rethinking supply chain models in the face of tariffs, trade instability, and geopolitical risk. A must-read for any team working to balance cost efficiency with operational resilience.

Want to see how enriched parts data and visual search can help your team react faster to trade policy changes?

Or visit www.partium.io to learn how we help global supply chains stay agile, accurate, and prepared—no matter what the trade landscape brings.

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

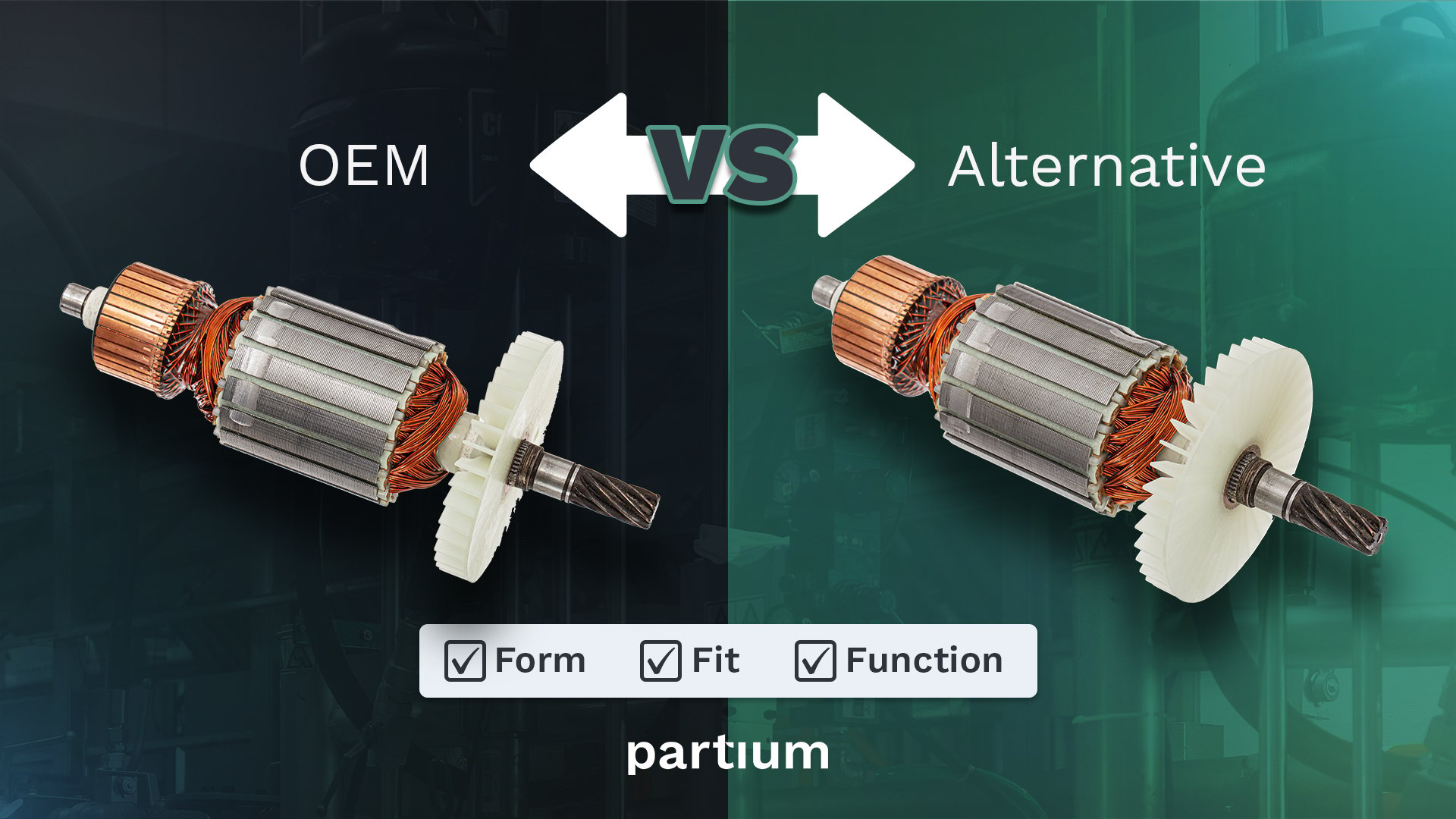

Quick Summary FFF (Form, Fit, Function) is the engineering discipline that turns a substitute part from a guess into an auditable decision. “Form” =...

Quick Summary NRND (Not Recommended for New Designs), PCNs (Product Change Notices), and LTBs (Last‑Time Buys) are everyday realities—not edge cases