Right Part, Lower Cost: How AI-Driven OEM Conversion Cuts Spend Without Adding Risk

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

3 min read

Linda Piercy

:

Oct 28, 2025 10:49:29 AM

Many organizations still issue purchase orders (POs) without full visibility into alternates, pricing, or obsolescence.

Tariffs, supply volatility, and legacy data errors amplify procurement risk.

Legacy “cleansing projects” only fix the problem temporarily — not sustainably.

Continuous AI-driven enrichment gives procurement teams confidence in every PO: verified alternates, updated pricing, and smarter sourcing.

Result: cost savings, better availability, and fewer last-minute surprises.

Procurement is under pressure. Tariffs are surging, lead times are unpredictable, and suppliers are revising prices almost weekly. Yet many organizations still approve purchase orders with limited or outdated information — relying on incomplete data from legacy ERPs or static supplier files.

That lack of visibility creates silent, recurring losses:

Buying parts at inflated prices due to unknown alternates.

Paying unnecessary tariffs or incorrect tax classifications.

Ordering obsolete items that delay production and require emergency sourcing.

Each of these issues might seem small, but across thousands of POs, they turn into a serious margin leak.

Traditional data “cleansing” projects are like spring cleaning — everything looks great for a few months, then the clutter returns.

The reason?

Most companies treat data as a project, not a process. Once new parts, catalogs, or suppliers enter the system, errors, duplicates, and outdated attributes creep back in.

Worse, traditional cleansing relies on manual or offshore work — expensive, slow, and disconnected from real-time operations.

Even well-known “data management” tools fall short because they work outside the ERP ecosystem — meaning the data goes stale again before the next purchase cycle.

Partium takes a different approach — one built for the speed and complexity of modern supply chains.

Instead of one-time fixes, Partium continuously enriches and governs parts data using industrial-grade AI.

That means:

Verified alternates: Identify compatible or equivalent parts before purchase.

Live pricing and obsolescence data: Connect catalog data to real-world market intelligence.

Continuous governance: Every new record, correction, and search improves the model — automatically.

This isn’t a static enrichment exercise — it’s a living, learning system that evolves with your procurement environment.

When buyers can see alternates, pricing, and lifecycle data before issuing a PO, they don’t just avoid bad buys — they make strategic ones.

As Prometheus Group defines it, true MRO data management is about deduplication, enrichment, standardization, and ongoing governance.

Procurement resilience isn’t just about surviving disruptions — it’s about anticipating them.

AI-driven enrichment gives organizations an edge:

Faster response to market shifts. When tariffs change overnight, pricing updates instantly.

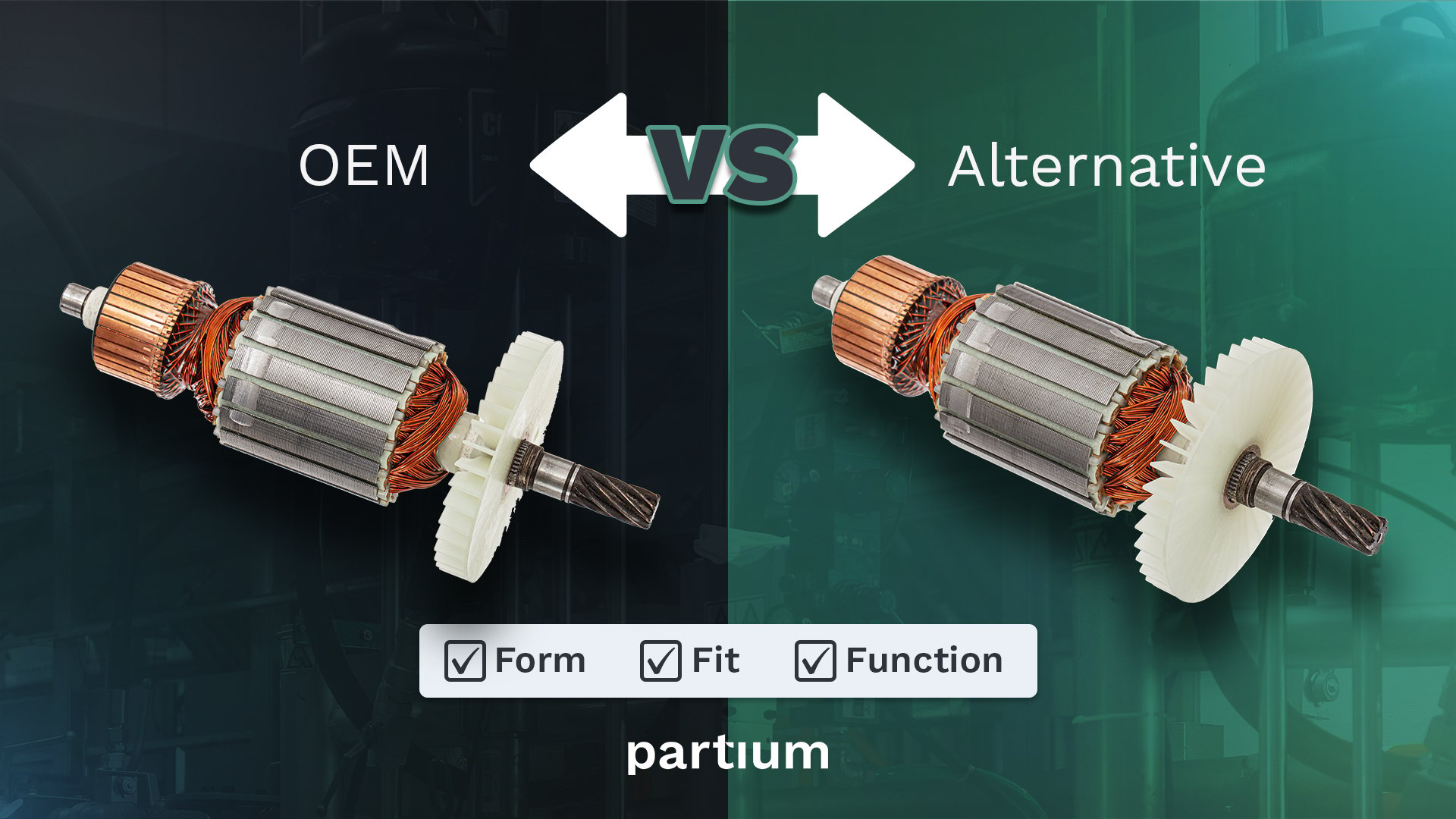

Smarter sourcing. Alternate parts are pre-qualified and verified, minimizing dependency on OEMs.

Reduced risk. Obsolescence tracking keeps teams from purchasing parts nearing end-of-life.

Better collaboration. Finance, planning, and supply chain teams all work from the same, trusted dataset.

The outcome? Lower costs, higher reliability, and confidence that every PO supports both operational uptime and financial performance.

ot ready for a full overhaul? You can start small today:

✅ Audit your catalog for duplicates, starting with your most frequently used parts.

🧑🔧 Empower technicians to upload photos and notes to capture tribal knowledge.

📦 Enforce key metadata (dimensions, OEM codes, specs) for all new entries.

⚠️ Set up drift alerts when naming conventions or standards start to slip.

📊 Tie improvements to KPIs: aim to cut search times by 30% and reduce mis-orders by 20%.

Each small step compounds — and together, they prepare your systems and teams for the next level of data enrichment.

Procurement doesn’t need more spreadsheets — it needs clarity.

Every PO should be informed by the best possible data: pricing, alternates, and part lifecycle status.

With Partium’s continuously enriched data, that visibility is built in — not bolted on.

Because the smartest purchase orders aren’t just approved… they’re optimized.

Want to dig deeper?

Poor procurement data doesn’t just inflate costs — it hides opportunities.

Explore how smarter data governance and continuous enrichment help organizations uncover alternates, lower sourcing costs, and make confident purchasing decisions.

Internal: What is Parts Intelligence – Learn how Parts Intelligence transforms static catalogs into dynamic, self-improving data ecosystems.

External: Verdantis: Materials Master Data Management Challenges – Discover why data quality and governance are critical to long-term supply chain success.

Want to see our core product - visual search in action?

👉 Watch the demo or explore the Partium Blog Series to see how Parts Intelligence helps procurement teams cut costs, manage obsolescence, and stay ahead of every market shift.

Quick Summary Locked into OEMs? AI makes cross-compatible alternatives obvious at the moment of approval. Clean the records you actually use...

Quick Summary FFF (Form, Fit, Function) is the engineering discipline that turns a substitute part from a guess into an auditable decision. “Form” =...

Quick Summary NRND (Not Recommended for New Designs), PCNs (Product Change Notices), and LTBs (Last‑Time Buys) are everyday realities—not edge cases