Why Maintenance Teams Can’t Afford Bad Parts Data (and What Works Instead)

Quick Summary Poor parts data is one of the most overlooked risks in MRO. Duplicates, metadata gaps, and workforce turnover drag down uptime, cost,...

3 min read

Linda Piercy

:

Jun 11, 2025 12:35:43 PM

Unplanned downtime, rising repair costs, and workforce fatigue have made reactive maintenance unsustainable. This article explores how industrial teams are transitioning to proactive MRO strategies using predictive analytics, digital 'spares' search, and intelligent tools like Partium to drive uptime, reduce costs, and build operational resilience.

Reactive maintenance increases costs, delays, and technician burnout

Proactive MRO enables smarter planning, faster part sourcing, and fewer breakdowns

Tools like AI-powered spare part identification streamline repairs

Predictive insights help avoid unplanned downtime and extend equipment life

The future of MRO is digital, data-driven, and technician-empowered

In the world of Maintenance, Repair, and Operations (MRO), many organizations are still stuck in reactive mode—constantly putting out fires rather than preventing them. This outdated approach leads to a cascade of inefficiencies.

Unexpected equipment breakdowns bring production lines to a halt, often costing thousands—or even millions—per hour in lost productivity.

Technicians waste time diagnosing avoidable issues, manually searching for spares, or performing redundant maintenance tasks.

Emergency repairs demand expedited shipping, premium-priced spares, and overtime labor, ballooning maintenance budgets.

The constant pressure to respond to last-minute crises wears down maintenance teams, leading to high turnover and reduced morale.

The new era of MRO is about being ready before things go wrong. Leveraging smart tools, real-time insights, and digital spare part strategies, leading organizations are adopting a proactive, preventive mindset.

IoT sensors track machine conditions such as temperature, vibration, and pressure to detect anomalies early.

Example: Vibration analysis alerts maintenance to worn bearings before failure occurs, allowing for scheduled replacement.

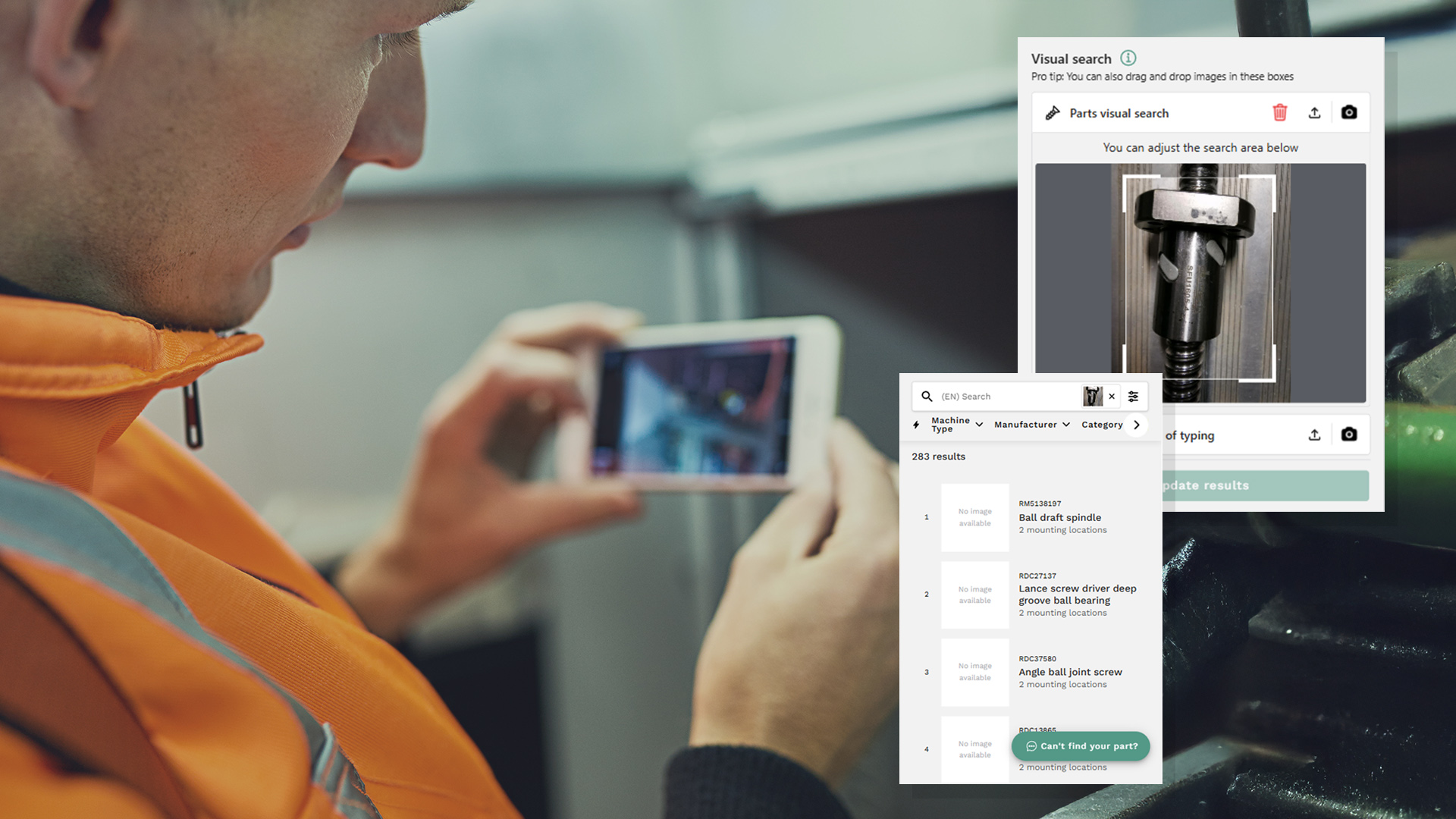

AI-powered tools like Partium help technicians identify exact parts using a photo, barcode, or part number—even when documentation is missing.

Impact: Reduces time spent hunting for spares, minimizes ordering errors, and speeds up repairs.

Digital platforms centralize manuals, SOPs, and repair histories, accessible from any mobile device.

Benefit: Standardized procedures help junior technicians perform complex tasks confidently and correctly.

Proactive MRO also means training staff to use the tools effectively—empowering them to fix problems independently.

Result: Reduced reliance on OEM field service, improved first-time fix rates, and a more capable internal team.

Analytics dashboards provide insights into spare part usage, failure trends, and inventory turnover.

Outcome: Smarter MRO planning, reduced parts hoarding, and optimized procurement.

Making the shift from reactive firefighting to proactive planning brings measurable improvements:

Reduced Downtime

Identify problems before they interrupt operations, keeping production running smoothly.

Lower Maintenance Costs

Avoid premium shipping, overtime labor, and excess spare part inventory with better forecasting.

Improved Safety Compliance

Catch safety risks early and perform inspections or maintenance on schedule.

Increased Technician Productivity

Let your team focus on preventive tasks instead of constantly reacting to emergencies.

Proactive MRO isn’t about buying software—it’s about creating a digital-first mindset and aligning your people, processes, and tools.

To get started, organizations must invest in:

Predictive analytics and condition monitoring

AI-based spare part identification systems like Partium

Real-time data collection from equipment sensors

Accessible digital knowledge hubs

Technician training in digital maintenance workflows

As operational complexity grows, proactive MRO isn’t just a good idea—it’s a competitive necessity.

The era of reactive maintenance is ending. Businesses that continue to rely on firefighting will face higher costs, lower uptime, and greater workforce stress.

Start transforming your MRO strategy today by evaluating your data infrastructure, digitizing your spares identification, and training your team to embrace modern tools. The faster you move toward a proactive, intelligent maintenance model, the better positioned you’ll be to outlast disruption and outperform the competition.

Interested in taking your MRO strategy to the next level? These expert resources provide a deeper dive into spare parts optimization, asset availability, and cost-effective maintenance operations—key pillars for any high-performing maintenance and reliability program.

This guide breaks down how AI, data enrichment, and visual search are transforming spare parts management from a reactive cost center into a proactive driver of uptime, efficiency, and service success. Ideal for teams seeking to modernize their MRO workflows with intelligent technology.

McKinsey outlines how predictive maintenance, clean data, and digital tools are redefining MRO excellence. A must-read for anyone working to balance inventory costs, reduce unplanned downtime, and build resilience into their asset lifecycle management strategy.

Want to stop wasting time searching for spare parts?

🎥Watch our search in motion here:

See how your team can identify the right part in seconds, reduce repair times, and improve first-time fix rates—online or offline.

👉 Visit www.partium.io to discover how proactive MRO starts with better spare part intelligence.

Quick Summary Poor parts data is one of the most overlooked risks in MRO. Duplicates, metadata gaps, and workforce turnover drag down uptime, cost,...

Quick Summary AI is transforming railway maintenance by reducing manual effort, accelerating part identification, and preventing unplanned downtime....

Quick Summary Maintenance, Repair, and Operations (MRO) processes are often overlooked—yet they hold some of the biggest cost-saving opportunities in...