Your ERP Isn’t the Problem — Your Parts Data Is

Quick Summary Most ERP, EAM, and procurement tools fall short — not because they’re flawed, but because they depend on inconsistent, fragmented...

3 min read

Linda Piercy

:

Jun 4, 2025 10:58:52 AM

20–30% of tail spend goes unmanaged due to poor parts data.

Inconsistent part records lead to duplicate orders and inflated inventory.

Parts Intelligence tools automate cleansing, enrichment, and sourcing.

Procurement teams that clean their top SKUs can cut costs by up to 12%.

Strategic data management accelerates procurement cycles and boosts supplier relationships.

Up to 30% of tail spend is unmanaged due to incomplete data, off-catalog buys, and one-time orders.

Inconsistent descriptions and part numbers generate multiple POs for the same part, inflating costs and workload.

Inaccurate data creates last-minute sourcing needs that lead to higher shipping fees and expedited pricing—sometimes inflating costs by up to 15%.

When rushed orders, mismatched deliveries, and returns pile up, trust with suppliers erodes, affecting future collaboration and pricing.

Contract negotiations and supplier performance metrics rely on clean, consistent SKU data.

From ESG compliance to conflict minerals reporting, incomplete part data increases audit risks and regulatory fines.

Inaccurate usage and demand data leads to shortages of critical spares or excess, obsolete inventory.

Initiatives like supplier portals and AI-powered sourcing will fail without a foundation of standardized, enriched part records.

| Step | Action | Impact |

|---|---|---|

Audit & Score |

Measure duplicate rates, missing attributes, and errors in ERP or purchasing systems |

Identifies pain points and quick-win opportunities |

Prioritize High-Spend SKUs |

Focus cleansing efforts on SKUs with high spend or high operational impact |

Maximizes ROI of your data improvement initiative |

Establish Governance |

Assign data stewards, set entry standards, and define KPIs (e.g., <2% duplicate rate) |

Builds accountability and ensures long-term data consistency |

Integrate & Automate |

Use Parts Intelligence tools to auto-standardize part numbers and attributes |

Reduces manual work and improves system reliability |

Monitor & Iterate |

Implement dashboards and anomaly detection for ongoing quality control |

Maintains clean catalogs and prevents regressions |

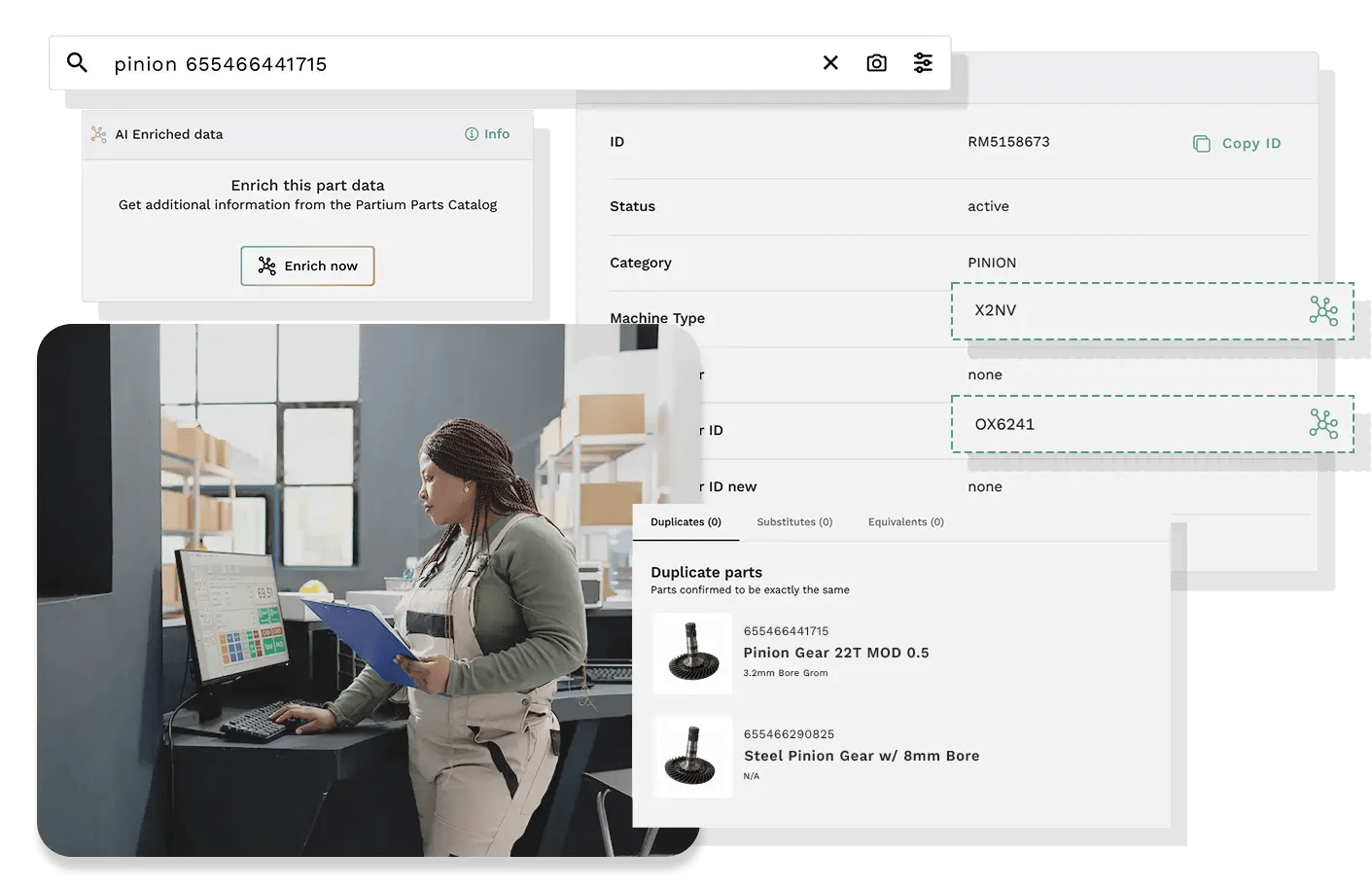

ERP systems were not built to handle the complexity of spare parts data. That’s where Parts Intelligence platforms step in.

Standardizes part descriptions, units, and vendor fields to eliminate duplicates and normalize entries.

Adds missing attributes like weight, material, dimensions, manufacturer details, or lifecycle status for smarter purchasing.

Links OEM parts with aftermarket or alternative suppliers—unlocking negotiation leverage and risk diversification.

Find parts using text, barcode, image recognition, or BOM upload—even when master data is incomplete or inconsistent.

12% reduction in spend through duplicate elimination and smarter sourcing

30% faster lead times with better part discovery and streamlined workflows

More accurate RFPs and negotiations powered by reliable item-level data

Start with the 20% of SKUs that drive 80% of spend.

Deploy rule-based or AI-driven duplicate checks to eliminate redundant entries.

Make a live catalog accessible across procurement, maintenance, and supplier teams.

Equip procurement, finance, and MRO staff with the tools and standards to maintain data hygiene.

Report monthly on duplicate rates, error frequency, and catalog accuracy to drive continuous improvement.

Procurement is no longer just about cutting costs—it’s about driving strategic value. But no sourcing strategy, AI initiative, or e-procurement platform will succeed without clean, accurate part data at the foundation.

Poor parts master data isn’t just a technical debt—it’s a daily financial and operational liability.

By investing in Parts Intelligence tools and sound data governance, procurement leaders can:

Slash emergency and duplicate purchases

Shorten sourcing cycles

Build stronger supplier relationships

Drive digital transformation outcomes

Now is the time to cleanse your catalog, enrich your top SKUs, and operationalize intelligent procurement. The smarter the data, the smarter the decisions—and the stronger your competitive edge.

Looking to deepen your strategy around data-driven parts management and procurement efficiency? These handpicked reads dive into the operational and commercial impact of poor parts data—and how forward-thinking companies are using Parts Intelligence, data harmonization, and enriched metadata to transform their aftersales and maintenance operations.

Here are more resources to explore:

The Hidden Costs of Poor Spare Parts Master Data – Understand how fragmented, inaccurate data hurts service performance, slows procurement cycles, and increases unplanned downtime.

McKinsey's latest insights on the future of procurement emphasize the strategic shift from transactional buying to data-driven, value-focused decision-making. Clean, structured parts data is foundational to this evolution—supporting predictive analytics, automation, and resilience across global supply chains. As McKinsey notes, organizations that modernize procurement with intelligent tools and accurate data are best positioned to unlock speed, savings, and agility.

🔗 Read the McKinsey article here

🎥 Watch: How Parts Intelligence Cleans and Enriches Procurement Data

Quick Summary Most ERP, EAM, and procurement tools fall short — not because they’re flawed, but because they depend on inconsistent, fragmented...

Quick Summary In B2B environments, poor data quality can silently erode efficiency, inflate spare part costs, and slow operations across the board....

Quick Summary Supply chain leaders and executives know that flawless inventory data is the backbone of operational resilience and cost control. Yet...