Your ERP Isn’t the Problem — Your Parts Data Is

Quick Summary Most ERP, EAM, and procurement tools fall short — not because they’re flawed, but because they depend on inconsistent, fragmented...

3 min read

Philipp Begala

:

Jun 10, 2025 9:53:31 AM

Spare parts data quality issues silently drain profitability and efficiency.

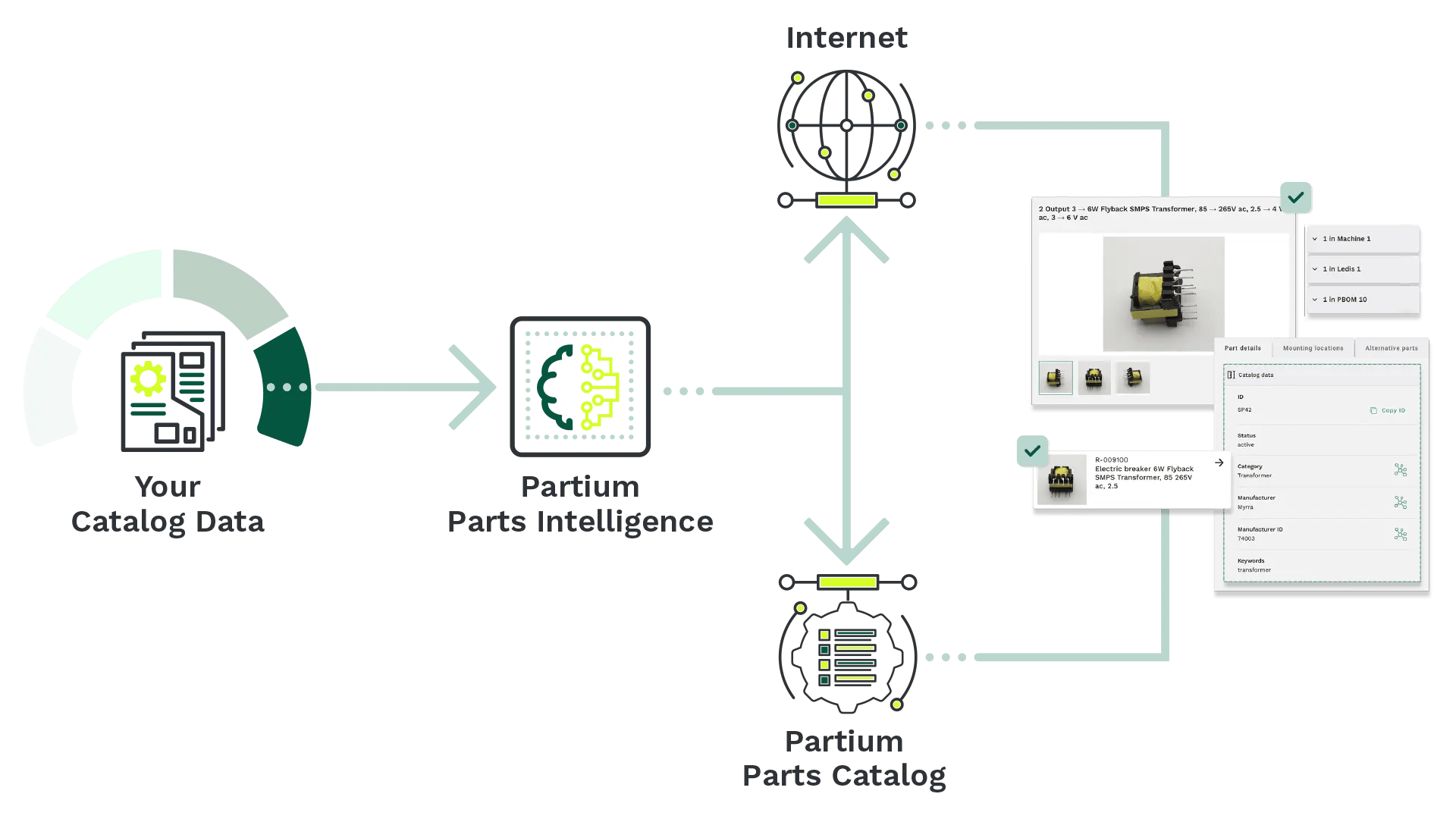

Self-healing data systems use AI to automatically cleanse, standardize, and enrich spare parts master data.

These systems reduce downtime, eliminate duplicate records, optimize inventory, and improve procurement.

AI-powered enrichment transforms part records into high-value assets that support MRO, engineering, and supply chain teams.

Spare parts are essential to keeping operations running, yet most organizations struggle with poor-quality master data. Duplicate entries, outdated information, and missing technical specs are all too common. These aren’t just IT issues—they lead to procurement mistakes, inflated inventories, and costly delays.

Self-healing data systems use AI to detect and resolve data issues automatically. These systems analyze spare parts master data in real-time to identify anomalies and take corrective actions with minimal human intervention.

Automated data cleansing

Real-time anomaly detection

Standardization across part attributes

Continuous enrichment from validated sources

Poor-quality data is a silent killer in spare parts management. In the field, this leads to real and measurable inefficiencies:

Search delays: Techs can't find parts due to inconsistent names.

False stock-outs: Parts appear out of stock due to duplicate listings.

Overstocking: Inaccurate records lead to excess, unused inventory.

Procurement inefficiencies: Sourcing gets bogged down by bad descriptions and misclassified vendors.

According to industry research, 5–15% of parts records are duplicates and 25–40% contain errors.

AI-driven data cleansing transforms manual, error-prone processes into automated, real-time improvements.

Uses NLP and fuzzy logic to detect duplicates and normalize records

Standardizes part names, formats, and supplier info

Flags invalid fields and cross-references manufacturer catalogs

Corrects values using external databases and OCR tools

Example: If “SEAL, HYDRAULIC” and “HYDRAULIC SEAL” appear as different SKUs, AI can consolidate them into one record and verify technical specs automatically.

Data enrichment builds on cleansing by enhancing each record with missing or contextual data.

Manufacturer cross-references and full names

Missing specs like dimensions, voltage, and materials

Product images and CAD files

Classification tags and metadata for filtering and discovery

Enriched records enable smarter search, better analytics, and seamless integration into MRO and ERP systems.

Investing in clean, enriched, and automated spare parts data pays off across the organization:

Faster Repairs: Techs find the right part in seconds

Reduced Inventory: No more hoarding unnecessary parts

Better Procurement: Accurate data means better vendor terms and fewer errors

Lower Costs: Reduced downtime, better planning, and fewer emergency buys

Bad data is no longer something you have to live with. AI-powered self-healing systems can automatically cleanse, enrich, and maintain your parts data—turning what was once a liability into a strategic advantage.

The future of spare parts management is intelligent, automated, and data-driven. It’s time to let your system do the work.

Looking to deepen your understanding of parts data, procurement efficiency, and digital transformation in maintenance and supply chain operations? These resources offer expert insights and practical guidance to take your strategy to the next level:

The Hidden Costs of Poor Spare Parts Master Data

Explore how data inaccuracies lead to procurement inefficiencies, excess inventory, and extended downtime—and how to fix it.

Spend Matters: A Procurement Guide to Data Accuracy and Parts Intelligence

A strategic overview of how accurate, enriched parts data is reshaping the future of procurement, from sourcing to inventory optimization.

To stay competitive, industrial organizations must treat clean, reliable data as a core asset—not an afterthought. The future of digital transformation hinges on the ability to automate and optimize operations with trusted information.

A recent report by Gartner emphasizes this shift:

👉Data Quality: Gartner: Best Practices for Accurate Insights

This article explains how poor data quality sabotages digital initiatives and outlines the key pillars of a robust data quality strategy. It’s a must-read for operations and IT leaders tasked with transforming asset-heavy environments

Discover how Partium’s AI-powered data cleansing transforms messy, inconsistent spare parts data into clean, structured, and searchable records—automatically. This short video walks you through how our solution detects duplicates, standardizes attributes, and sets the foundation for a smarter parts catalog.

Watch now to see how clean data can power your entire MRO and procurement workflow

Quick Summary Most ERP, EAM, and procurement tools fall short — not because they’re flawed, but because they depend on inconsistent, fragmented...

Quick Summary In B2B environments, poor data quality can silently erode efficiency, inflate spare part costs, and slow operations across the board....

Quick Summary Supply chain leaders and executives know that flawless inventory data is the backbone of operational resilience and cost control. Yet...